Schwartzentruber-Renon PR or RKS wit h WS mixing rules No No Binary iteration coefficients available? Operating pressure low to medium ≤ 10 bar? Peng-Robinson (PR) Soave-Redlich-Kwong (SRK) Lee-Kesler-Plöcker Vapor – Liquid Equilibrium Example (Dechema Chemestry Data Series)ĭecision tree for the selection of the thermodynamic property model Equations of state modelĪctivity coefficient model Pressure Polarity Standard State fugacity c P v 0 0 sat 0 i f i pi i exp sat dP pi p i RT The vapor phase can be considered ideal therefore

In this case, thermodynamic models are required forĪnd i (from a liquid-phase activity coefficient model)Īctivity Coefficient Method At moderate pressures: # i is the vapor - phase fugacity coefficient i is the liquid - phase activity coefficient 0į i is the fugacity of Comp. i and i are the vapor and liquid phase fugacity coefficients, respectively P is the system pressure Where yi and xi are the mole fraction of Comp i in the vapor and liquid phases, respectively V The fugacity coefficients for each phase are determined with the following expression Where yi and xi are the mole fraction of Comp i in the vapor and liquid phases, respectively V L i and i are the vapor and liquid phase fugacity coefficients, respectively Where f i is the fugacity of Component i in Phases I, II,… Fį i V is the fugacity of Component i in the vapor phase f i L is the fugacity of Component i in the liquid phase Phase Equilibrium A closed system that contains more than one phase, at constant Pressure and Temperature, is at equilibrium if: I Property packages are used to predict the phase equilibrium behavior of pure components and mixture systems Solving the mass and energy balances for these operations necessitates predicting theĮstimation of physical properties can consume up to 90% of the computation time of a simulation. Phase equilibrium represent one of the most important physical properties, as many chemical processes simulations involve distillation, stripping, evaporation or liquid-liquid separation. Supply estimates for a number of different physical properties while the simulation is running. – Rigid direction of computation, normally outputs from inputs. – Present difficulties with flowsheets involving a large number of recycle streams. – Need for topological analysis and systematic initialization of tear streams. + The unit blocks can be easily added to or removed from the flowsheet.ĭisadvantages – SM is well suited to process simulator, but not to design or optimization, since an iterative procedure is required to satisfy the constraints. Specific solution methods are developed for each process unit. Sequential – Modular Process Simulators Advantages + Easy programming and maintenance.

Fwsim tuturial software#

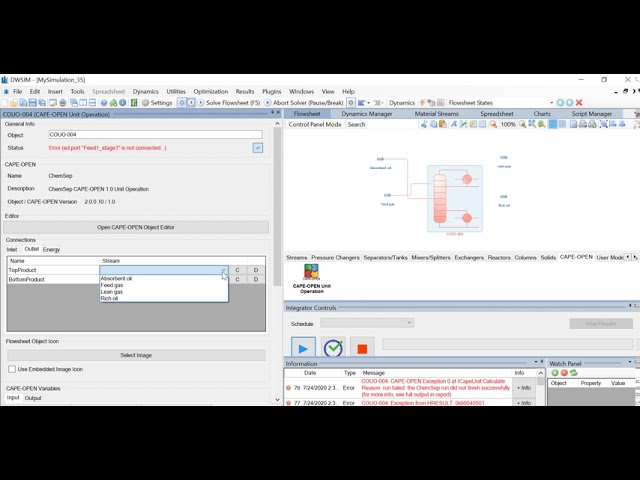

Sequential – Modular Process Simulators Graphical User Interfaceįigure reproduced from Introduction to Software for Chemical Engineers, M. Simultaneous-Modular Combination of Sequential-Modular and Equation Oriented approachesĬommercial Steady-State Process Simulators Sequential – Modular approachįree Steady-State Process Simulators Sequential – Modular approach

The computation of the flowsheet takes place unit by unit following a calculation sequence.Įquation-Oriented (Simultaneous-Nonmodular) The complete model of the flowsheet is expressed in the form of one large sparse system of nonlinear algebraic equations that is simultaneously solved for all the unknowns.

Fwsim tuturial code#

Sequential-Modular Based on the concept of modularity, which extends the chemical engineering concept of the unit operation to a “unit calculation” by the computer code responsible for the calculation of single process unit. Flowsheeting can be used as aid to implement a plantwide control strategy, as well as to manage the plant operation. Mond Monday ay, Octo Octobe berr 24th 24th 2016 2016 įlowsheeting Flowsheeting is a systemic description of material and energy streams in a process plant by means of computer simulation with the scope of designing a new plant or improving the performance of an existing plant. Simu Si mula lati tion on of Di Dist stil illa lati tion on Co Colu lumn mnss Mond Monday ay, Octo Octobe berr 17th 2016 Simu Si mula lati tion on of Ch Chem emic ical al Rea eact ctor orss Mond Monday ay, Octo Octobe berr 10th 2016 Introduction to Sequential – Modular Steady State Process Simulators Introduction to Chemical Process SimulatorsĬontents Mond Monday ay, Octo Octobe berr 3rd 2016 INTRODUCTION TO CHEMICAL PROCESS SIMULATORS DWSIM Chemical Process SimulatorĪ.

0 kommentar(er)

0 kommentar(er)